Automotive "interior and exterior decoration parts" robot processing technology scheme

Release Time:

2022-11-30 10:27

Components of automobile interior and exterior decoration:

From the perspective of structure, automotive exterior parts mainly include trim, trim, functional structure, body structure, chassis structure (new energy vehicle battery box), lights, door handles, sunroof, etc.

Automotive interior parts are mainly divided into instrument panel, steering wheel, door inner guard panel, ceiling, seats, lighting, column guard panel, trunk (trunk) and so on.

Materials used for automobile exterior parts:

Automobile exterior parts commonly used materials are ABS (acrylonitrile - butadiene - styrene plastic), carbon fiber composite materials, PP (polypropylene), ASA(styrene, acrylonitrile and acrylic rubber copolymerization), l according to the specific parts system performance requirements of the materials used are different.

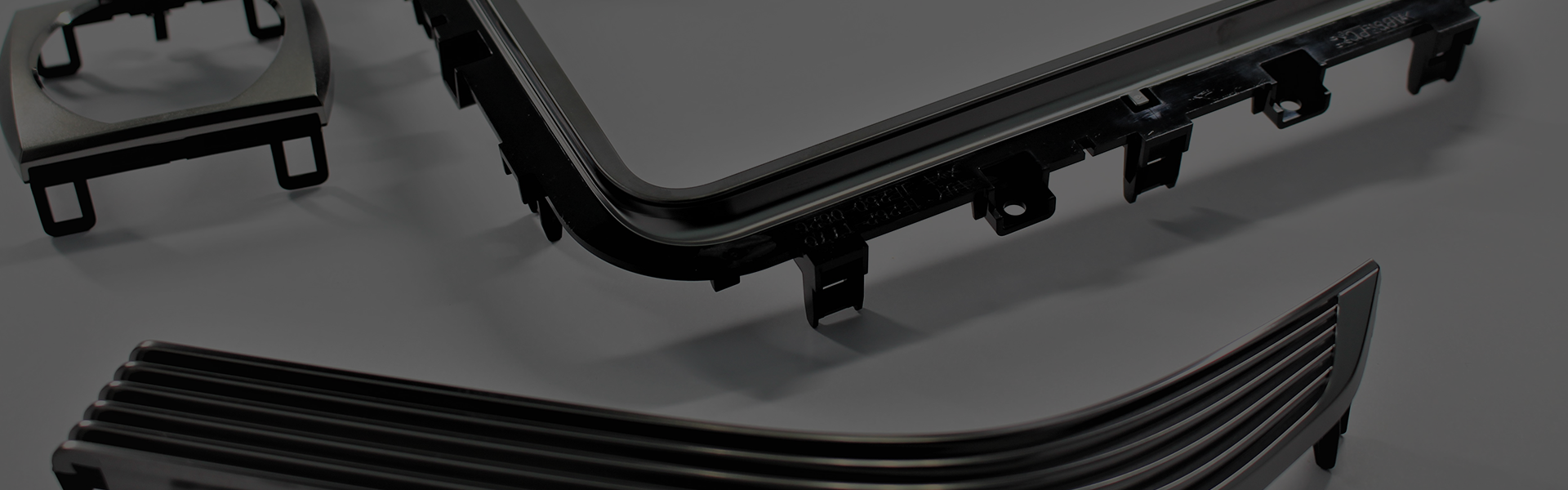

Auto exterior parts structure dismantling:

1. Frieze (5 majority)

Automobile exterior decoration strip is mainly used in automobile external water cutting/internal water cutting, door frame trim strip assembly/side trim strip assembly, top cover trim strip assembly, side rear window assembly, anti-clamp strip assembly, using plastic TPV, PVC, PP, etc., a variety of processes.

2. Accessories (6 majority)

Automotive exterior parts are mainly used in radiator grille assembly, rear spoiler assembly, rear license plate trim assembly, cover plate, radar label, radar grille, using PC+ABS, PC+PET, ASA and other materials.

3. Functional structural parts (most of them)

Automotive exterior functional structural parts are mainly used in luggage rack assembly, top ventilation window guide assembly, using PP, PPLGF, carbon fiber or glass fiber composite materials processing.

4. Body structural parts (4 most)

Automotive exterior body structure parts are mainly used in door frame assembly, aluminum door frame assembly, guide rail assembly, seat slide rail assembly, using cold rolled galvanized sheet, aluminum alloy material processing.

5. Battery case

It is placed in the chassis of the vehicle, as the bearing and protection unit of the power battery system of the new energy vehicle. It adopts the composite of aluminum extrusion, aluminum stamping, aluminum die casting and other materials, and combines various connection technologies such as welding, bonding and riveting to meet the requirements of function and strength while achieving better lightweight.

Which auto parts will be involved in industrial robot processing application:

1, automobile interior and exterior trim, aluminum alloy decorative strip, processing robot cutting, drilling, grinding deburring.

2, automobile exterior aluminum alloy luggage rack, processing technology robot deburring.

3, automotive interior SMC composite trunk (trunk), processing robot cutting, milling, drilling.

4, automobile exterior decoration acrylic taillight frame, processing technology robot deburring.

5, automotive interior engine cylinder block, cylinder head, processing robot floating deburring.

Related News

2021-09-15

Quality design of automobile exterior trim

In China, which has the world's automobile market, in order to meet the needs of customers, a factory was built in the electroplating industrial base of Yamen Town, Jiangmen City, Guangdong Province, China. Like the Japanese headquarters, the company takes care of the environment as its own responsibility, uses skilled and advanced electroplating technology, implements high-quality and diversified electroplating production, and provides high-quality services to global customers.

CONTACT US

Address: Room 211B, New Fortune Environmental Protection Electroplating Base, Yamen Town, Xinhui District, Jiangmen City, Guangdong Province, China