The development trend of automotive trim system

Release Time:

2022-11-30 10:28

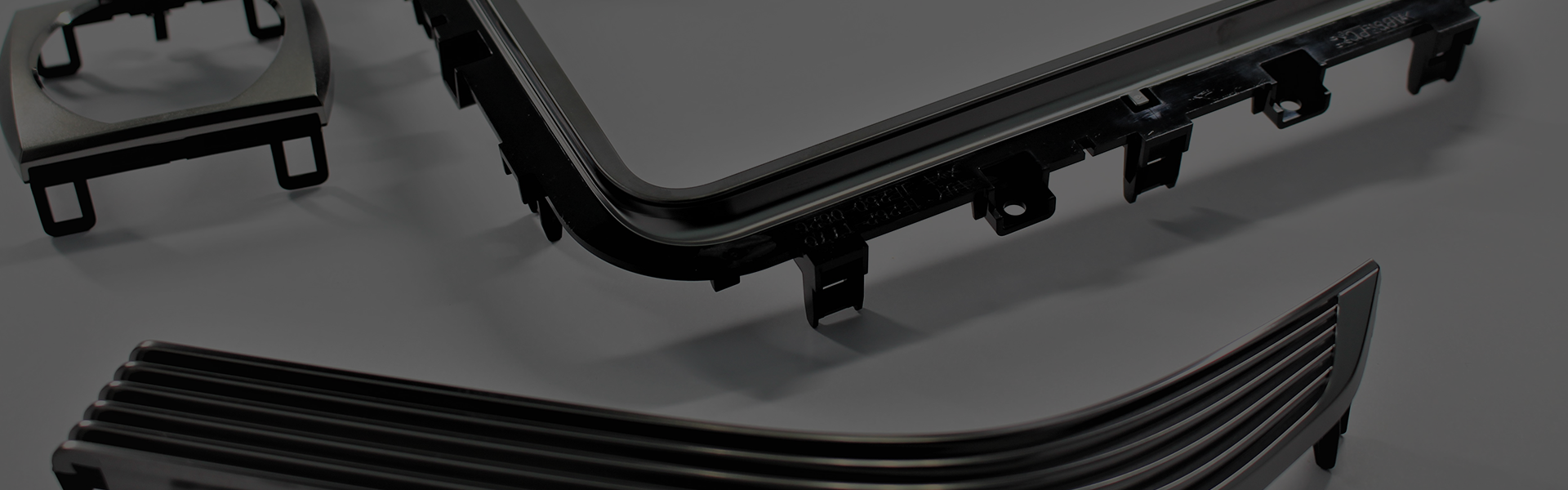

The development trend of "new Four Modernizations" in automobile industry also puts forward new requirements for the design and development of trim system. As one of the important subsystems of interior and exterior decoration, the trim system has shown remarkable features such as diversified process and intelligent parts while conforming to this development trend.

Process diversified trim system involves more than 20 kinds of molding process and surface treatment process, which is itself the "material library" and "process library" of interior and exterior decoration system. In recent years, with the progress of technology, more and more new processes are applied to the trim system, showing a trend of economic and quality oriented development.

Water assisted forming

Hydraulic auxiliary molding can be the luggage rack longitudinal beam, front and rear bracket, front and rear trim cover and other sub-parts integrated into integral parts. The picture shows a luggage rack made of BASF material. From the current more than ten seed parts simplified to five or six seed parts, auxiliary molding greatly simplifies the types of sub-parts and internal assembly relations, and eliminates the process of polishing aluminum profiles, can achieve about 35% cost reduction and about 50% weight reduction, the follow-up will further expand the scope of application.

Water-assisted luggage rack

Color band injection

Using colored raw materials directly injection molding, molding products to achieve the surface treatment effect of spray paint, can replace the corresponding color of the paint process. Compared with spraying process, this process has the advantages of more efficient, more environmental protection and lower cost. At present, this process has been mass-produced in the wheelbrow assembly and anti-scratch strip assembly of some new energy models. In the future, more spray painting parts will be replaced by color injection.

High light injection

Direct use of high light material injection molding, at the same time for mirror level polishing of the mold, so that the parts out of the injection to achieve high light effect, can replace the complex high light spraying process. Compared with the high light spraying process, the process has the advantages of more efficient, more environmental protection, more free modeling and more cost saving. Future A/D column trim assembly, tail door spoiler assembly, rear plate trim assembly, signage and other parts will further apply this process.

Related News

2021-09-15

Quality design of automobile exterior trim

In China, which has the world's automobile market, in order to meet the needs of customers, a factory was built in the electroplating industrial base of Yamen Town, Jiangmen City, Guangdong Province, China. Like the Japanese headquarters, the company takes care of the environment as its own responsibility, uses skilled and advanced electroplating technology, implements high-quality and diversified electroplating production, and provides high-quality services to global customers.

CONTACT US

Address: Room 211B, New Fortune Environmental Protection Electroplating Base, Yamen Town, Xinhui District, Jiangmen City, Guangdong Province, China