Emi Plating - Anti-shielding Electromagnetic Wave Interference

What is EMI

Electromagnetic Compatibility (Electromagnetic Compatibility) abbreviation EMC means that an electronic device neither interferes with other devices nor is it affected by other devices. Electromagnetic compatibility, like the safety we are familiar with, is one of the most important indicators of product quality. Safety concerns people and property, while electromagnetic compatibility concerns the protection of people and the environment. The phenomenon of interference between electromagnetic waves and electronic components is called EMI (Electromagnetic Interference). For example, the common "snowflakes" on the TV screen indicate that the received signal is interfered.

At present, there are the following shielding processes in the industry:

1: Spraying conductive paint refers to directly spraying a metal paint on the product to achieve the effect of conductive shielding. This kind of paint is made by grinding metal into powder and adding some resin for mixing. Mainly copper oil, silver copper, nickel oil, silver oil and so on. This type of process generally has simple processing procedures and low cost (except for silver conductive paint), but its resistance will be relatively large and the shielding effect will be poor. (It is well known that the smaller the unit resistance, the stronger the conductivity, the better the shielding effect) and the adhesion is very bad. A large amount of metal powder will fall off when tested with 3M tape. Because the whole body of this kind of paint is water-soluble, it is usually diluted with alcohol, and it cannot adhere to the plastic well when sprayed on the product.

2: Vacuum coating technology content and equipment investment requirements are relatively high, and many factories have high costs, difficult control, and low production capacity. In terms of product quality, there are also disadvantages such as high resistance, and the most important thing is weak oxidation resistance (the metal film sputtered on the product is easily oxidized when exposed to air).

3: EMI electroplating is also known as water plating and sink plating, that is, electroless copper plating and nickel plating. It is a relatively mature shielding process, which is very popular in Japan, Europe and the United States. It consists of primer spraying, chemical copper deposition, chemical nickel deposition and other processes. Primer spraying mainly serves as a catalyst for priming the parts that require EMI. Electroless copper uses catalysts to react with chemical potions to separate and adsorb copper ions on the product to form a copper film (2-3um). Electroless nickel is due to copper The layer is easily oxidized when exposed to the air, so nickel plating on the copper layer can protect the copper layer from oxidation. The resistance of the product using this process can reach a plane 10mm less than 0.1 ohm, strong adhesion and not easy to oxidize.

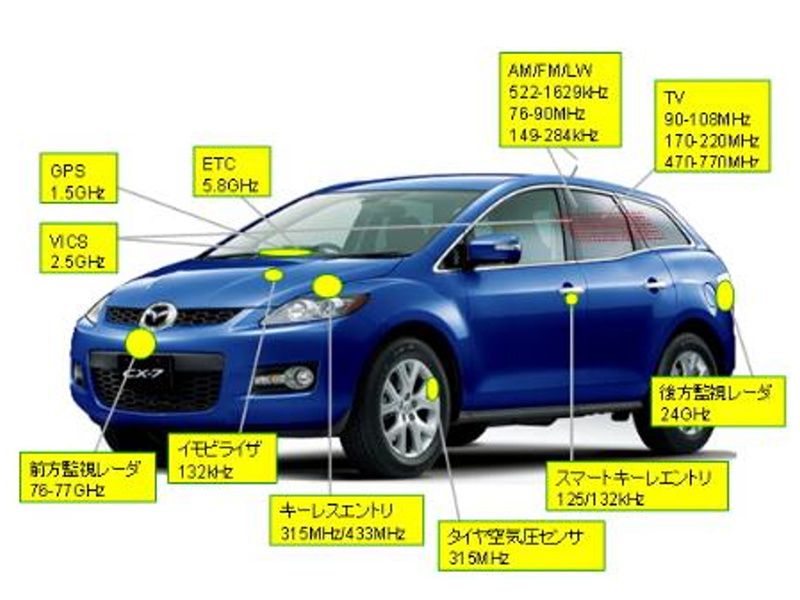

It is necessary to avoid the influence of electromagnetic waves, and the safety of vehicles must be protected. EMC (electromagnetic wave shielding) countermeasure plating for automotive parts

Automotive Electromagnetic Wave Detection

Sources of Electromagnetic Waves in the Cockpit

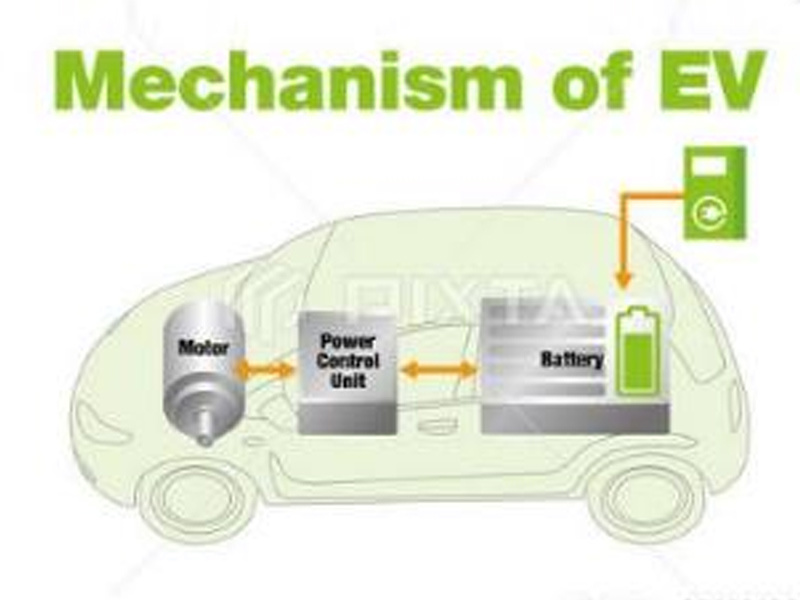

The Mechanism of Electric Vehicles

Need to prevent electromagnetic waves from interfering with electronic equipment

CISPR 25⇒Plating measures attract attention again! !

※CISPR: International Special Committee on Radio Interference GB/T 18655 (equivalent to CISPR25)

The effect of electroplating

● Provide conductivity, anti-static countermeasures, etc. to impart properties to resin plastics

● High rigidity, increased strength, improved tolerance

● Electroplating for EMC, EMI, countermeasures

● Thick plating film with better conductivity for noise countermeasures such as mobile phones and computers. Compared with anodizing, electroplating will make the appearance and electrical conductivity of the object more excellent.

What are electromagnetic waves? Classification of Electromagnetic Waves

● Electromagnetic waves are often widely used in broadcasting and wireless communications. When these equipment devices are working, they will generate electromagnetic waves and noises, which will interfere with each other.

● In recent years, plastic parts tend to increase in order to reduce costs through automation and weight reduction. However, unlike metal parts, plastic parts do not have the function of shielding electromagnetic waves. In addition, in order to realize the practical use of automatic driving of vehicles, it is increasingly necessary to deal with electromagnetic wave interference. Under such circumstances, electroplating, a technology that has been maturely used as early as 1985, and which protects the surface of plastic parts used in office equipment such as personal computers and medical equipment from electromagnetic waves, will attract more and more attention.

Electroplating of engineering plastics (namely: EMC, EMI countermeasure electroplating)

● 1u chemical copper treatment on the plastic, and then 0.25u chemical nickel treatment to prevent rust, can obtain electromagnetic wave shielding effect comparable to that of 3mm aluminum plate. This electromagnetic wave shielding plating on plastic has been widely used in OA machines and OA equipment such as computers since 1985 (the same below)

● Recently, there are more and more applications and loads of various electronic components & electronic systems in automobiles; on the other hand, due to the lightweight of automobiles, plastic parts have been widely used in casings, frames, Although connectors have the advantage of light weight, plastic parts do not have the function of electromagnetic wave shielding. Therefore, some form (ie, electromagnetic wave shielding plating) is required to deal with electromagnetic wave interference.

● In order to realize the practical use of automatic driving of vehicles, it is increasingly necessary to deal with electromagnetic wave interference.

● Shielding technology to prevent the noise generated by the internal engine, motor and other components, as well as to prevent the interference of external electromagnetic waves on the vehicle electrical appliances. Currently, it is maturely used in electroplating for electromagnetic wave shielding of OA machines and medical equipment.

● Automobiles are currently a mobile carrier that highly coexists with people. They work in a variety of environments, such as strong vibrations and harsh high and low temperature environments. Therefore, it is necessary to have quality that can adapt to the environment in all directions.

Electroplating of engineering plastics

● In the electroplating industry of so-called resin plastics, it is very difficult to electroplate engineering plastics, which are called engineering plastics and super engineering plastics (Engineering plastics) and super engineering plastics (Super engineering plastics), which have high strength and high heat resistance and can replace metal parts.

● Through the forward-looking layout, the company has mature experience in electroplating proofing and mass production of PPS, PBT, LCP, Glass, etc., which are relatively difficult to electroplate materials. components are widely used.

Platable resin material list

| Usually plastic | ABS, heat-resistant ABS, flame retardant ABS, PC/ABS |

| Engineering plastics | PC, PBT, PA, SPS, POM, PPE |

| Super Engineering Plastics | PES, PPS, PEI, LCP, PI, PEEK |

| Special Plastics | PC/ASA, PU, light molding material, 2-color molding material |

Features of Electromagnetic Wave Shielding Plating

● Compared with the electromagnetic wave shielding method using metal parts, it contributes to weight reduction, improvement of fuel efficiency, and cost reduction. In the frequency band from 10MHz to 1GHz, it exhibits a shielding effect equal to or better than that of metal.

● The shielding electroplating of engineering plastics has been proved to have the same electromagnetic wave shielding performance as metal parts.

● In recent years, as a means to reduce the weight of next-generation vehicles and improve fuel economy, electromagnetic wave shielding plating on engineering plastics has become the focus of attention; we have conducted various evaluations and tests, even engineering plastics Other special materials have also been tested and verified in advance.

● For electroplating of engineering plastics and special materials, please contact us!

In China, which has the world's automobile market, in order to meet the needs of customers, a factory was built in the electroplating industrial base of Yamen Town, Jiangmen City, Guangdong Province, China. Like the Japanese headquarters, the company takes care of the environment as its own responsibility, uses skilled and advanced electroplating technology, implements high-quality and diversified electroplating production, and provides high-quality services to global customers.

CONTACT US

Address: Room 211B, New Fortune Environmental Protection Electroplating Base, Yamen Town, Xinhui District, Jiangmen City, Guangdong Province, China